In the initial days of industrialization, we were not aware of the toxic outlets of those industries. As the number of industries increased, several toxic gases increased their amount in the atmosphere. These gases were made a bad impact on the workers as well as on the local people nearby the industry. To handle this hazard many rules and regulations had been made in industries whereas governments of several countries also made stringent laws to handle this scenario. In today’s article, we are going to discuss a gadget that played a role in industries to detect toxic gases. This is Toxic Gas Detector. Many of us know about it but few of them only know the inside structure of the gadget. That’s why we are here. So, without any further delay let get started.

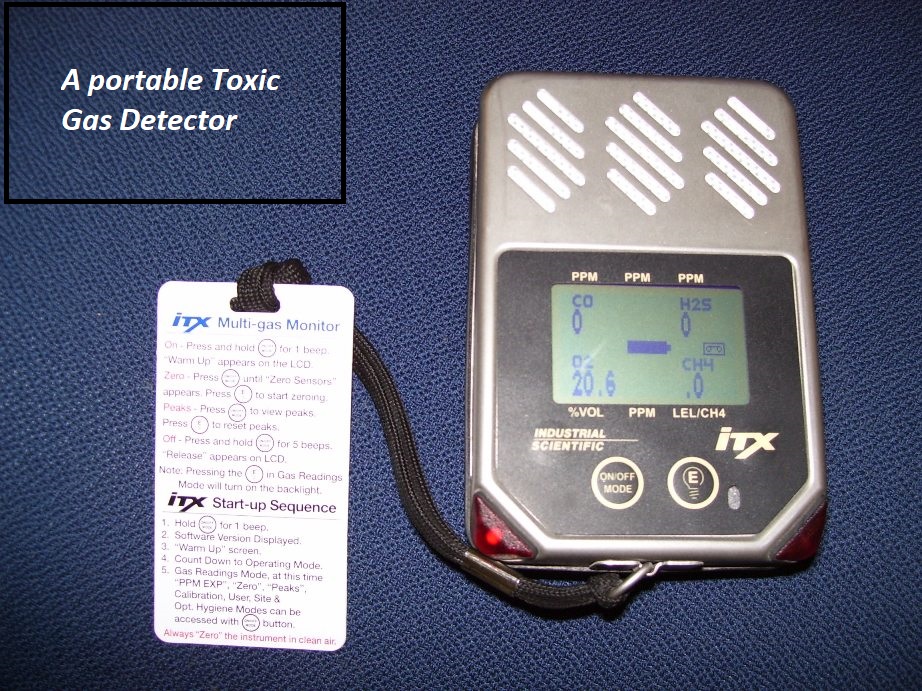

About a Toxic gas detector:

Monitoring harmful gases in the environment can be challenging but crucial to ensure the safety of the industrial working environment. All of us know that oxygen is a life gas but you know that a large amount of oxygen became toxic. Too much oxygen or other toxic gases like Hydrogen sulfide, Chlorine, Ammonia, or Carbon monoxide, can present new dangers to the employees, equipment, and local people also. Fortunately, a Toxic gas detector is here to help us. A toxic gas detector monitors the presence of gases in a specified area and sounds an alarm or loud horn when they reach dangerous levels. The gas detectors are typically installed at the locations where there is a potential for a gas leak, and where unsafe gas levels pose an immediate danger to people.

Engineering inside this:

We have discussed this safety gadget, now we are going to discuss its internal engineering that makes this gadget useful:

- Detection sensor

- Control board

- Power supply

- Monitoring unit

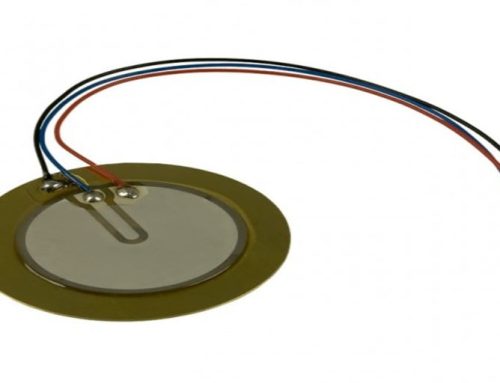

Detection sensor:

As we know different types of hazardous gases could be caused for serious illnesses in humans. In every toxic gas detector detection sensor is the electronic component that detects specific gas. For example, Ammonia is detected by one sensor whereas Carbon mono-oxide is detected by another sensor. In simple terms, every sensor has its specific gas detection ability. This is what we are looking for in Toxic Gas Detectors.

To get the more sensitive and accurate sensors Metal oxide gas sensors are best. They are highly sensitive and do their job precisely. Its working technique is not new. As we know they are made of semiconductors. The electrical resistance of semiconductor material changes on the adsorption of some gases and this change in resistance can be used to detect toxic or flammable gases, which even in very low concentrations can profoundly injure the human body.

Gas Detection sensor

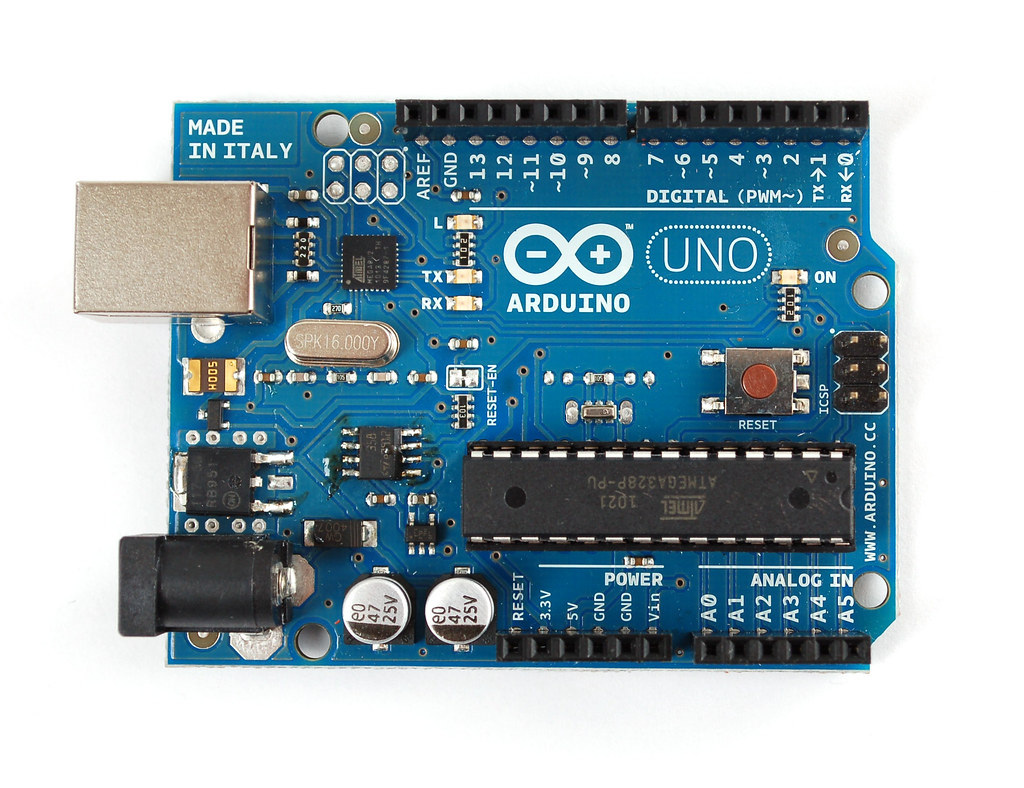

Control board:

The control board processes the received electrical signal from the gas sensor and sends the processed data to the monitoring or display unit also as per the gas levels it trigger the panic alarm. This board is the central point of the gadget. It is primarily based on a microcontroller or microprocessor based program to process the input electrical signal from the sensor. Every manufacturer of Toxic Gas Detector uses its program for processing. Once the toxic gas is detected or breaches certain threshold values then a panic alarm got triggered by the control unit to make awareness among the nearby people. To make a Toxic Gas Detector Arduino-UNO is a good option that made the entire system easy and fast.

Arduino UNO

Power supply:

This unit provides the required power supply to the entire circuit. Some of the Toxic Gas Detectors use batteries for the same. In general, it contains several electronic components similar to a mobile phone charger. Most industries use Online UPS as a power source for this kind of safety gadget.

Monitoring unit:

This is the user interface that provides certain levels of toxic gases in a focused area. Some of the manufacturers provide small LCD for monitoring purposes whereas some of them provide dedicated monitor displays with advanced examination features. It is mainly responsible to represent the value or level of toxic gases.

That’s how all of these units are combined to form a Toxic Gas Detector. Now we are going to focus on the working process of this interesting device that is a kind of safety wall of the industries.

Working process:

The working of this machine is simple. Once the sensor detects the toxic gas then a small electrical signal sends to the control unit. The Control unit works on this electrical signal and makes decisions as per their pre-programmed controller chips. After successful processing, the control board sends signals to the monitoring unit to display the required data for the user interface. If toxic gas detected by the sensor then control unit also trigger the panic horn or alarm to aware the nearby peoples.

Application:

Toxic gas detectors are widely used by industries including oil and gas, medical, fertilizers, mining, nuclear, construction, food and beverage, and other processing industries. These kinds of machines are used in workplaces to protect workers from toxic gases. This detector is also integrated with fire detection system to sense toxic gas leakage.

Thanks for reading. See you soon with another exploration!