At present entire world is moving towards clean and green earth. In this path, the automobile sector made a powerful impact on pollution-free transportation by making electric vehicles. These electric vehicles are runs on rechargeable batteries but one major drawback is the long charging period and low run period. Due to this limitation, most electric vehicles run into fixed periphery with a single charge. To overcome this problem Hybrid Electric Vehicles come into the role.

What is Hybrid Electric Vehicle?

Hybrid electric vehicles (HEVs) are powered by an internal combustion engine and electric motors, which uses stored electric energy from batteries. A hybrid electric vehicle does not use an external electric power supply to charge its batteries. Instead, the battery is charged through regenerative braking and by the internal combustion engine. In regenerative braking, the vehicle captures energy normally lost during braking by using the electric motor (here electric motor acted as a power generator) and storing the captured electric energy in the battery. HEVs can be categorized as Mild hybrids and Full hybrids.

Mild Hybrids:

These are also known as micro-hybrid vehicles. A mild hybrid vehicle uses a battery and electric motor to help power the vehicle and can allow the engine to shut off on short halting like stop-and-go traffic. This hybrid system cannot power the vehicle using electricity alone. These vehicles are cost efficient than full hybrid vehicles but provide less fuel economy.

Full Hybrids:

This hybrid design contains larger batteries and powerful electric motors; that can power the vehicle for short distances at slow speeds.

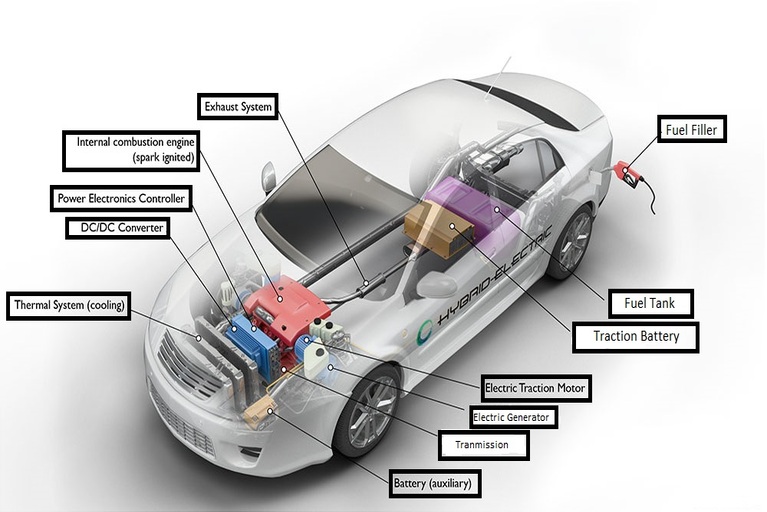

Components in Hybrid Electric Vehicle:

Auxiliary Battery:

In an electric vehicle, the low-voltage auxiliary battery provides an electric supply to start the car before the traction battery is engaged. This battery also provides power to vehicle accessories like the mobile charging port, music system, etc.

DC to DC converter:

This electronically designed unit is responsible to convert high-voltage DC power supply from traction battery to low-voltage DC power. Low-voltage DC power is used to recharge the auxiliary battery and run the various accessories of the vehicle.

Electric Motor- Generator:

Electric Motor-Generator is a single unit that performs the function of the motor as well generator. Here Electric motor is designed to generate electricity from the rotating wheels while braking, transferring that energy back to the traction battery pack. Some vehicles use Electric Motor-Generator whereas others use separate motors and generators to do the same.

Electric Traction Motor:

By using a traction battery power pack this motor drives the vehicle wheels. Some manufacturer uses motor-generator that performs both the drive and power regeneration function.

Exhaust system:

The exhaust system provides the path to exhaust gases from the engine out through the outlet pipe or tailpipe. A three-way catalyst is designed to reduce engine-out emissions within the exhaust system. Three-way catalysts are designed to perform multiple reactions and reactions simultaneously to convert air pollutants that are present in the exhaust to harmless gases.

Fuel filler:

A nozzle from a fuel dispenser attaches to the receptacle on the vehicle to fill the fuel tank.

Internal Combustion Engine:

In this engine ignition and fuel, combustion occurs within the engine itself and the engine partially converts the energy from combustion to work. Here fuel is injected into the combustion chamber, where it is combined with air, and the air/fuel mixture is ignited by the spark from a spark plug.

Power Controller:

This unit manages the current flow of the traction battery for the traction motor to control the speed of the vehicle.

Thermal system:

This system maintains a proper operating temperature in entire Electro-mechanical systems that include the engine, electric motor, power electronics, and other components.

Traction Battery:

It stores electricity for use by the electric traction motor.

DC to DC converter

Advantages of Hybrid Electric Vehicles:

Less Emission:

As we know hybrid vehicle contains electric motor as well as internal combustion engine, so they need less fossil fuel. As a result, they emitted less CO2. Additionally they have more efficient mileage than conventional cars.

Financial Benefits:

At present many governments provide tax credits and incentives for buyers and owners of hybrids. They are also exempt from environmental charges.

Disadvantages of Hybrid Electric Vehicles:

Less Power:

In these vehicles neither the internal combustion engine nor the electric motor works as strongly as conventional fossil fuels-based engine cars do. But Hybrid vehicles work just fine for normal driving if you are not expecting fast and furious driving.

Initial cost:

The initial cost of hybrids is more expensive than conventional vehicles in most cases.

Higher running costs:

Hybrids are continuously evolving and changing in design, due to this it may not be easy to find a mechanic with the required expertise.

Electrocution Risk:

The batteries in hybrids contain high voltage, which can increase the risk of the passengers and rescuers being electrocuted in the event of an accident

Thanks for reading. See you soon with another exploration!