It is strange when we heard about a printer who can print an object like a car? Are you agreeing with this statement? Most probably No! But it is true. In the initial days of printing our ancestors were used a manual or a mechanical printer to print any news or articles. I am not going to cover the whole journey of printing technology because it is not a one-day job. Evolution in electronics and mechanical engineering built a foundation in modern printers. Now we are at the level of technology to print an object via using a 3D printer (Here 3D stands for three-dimensional). Before going into the deep, let’s have a brief introduction to a 3D printer.

What is a 3D printer?

It is a kind of printer that uses a layering technique to create or print a three-dimensional object. The 3D printer uses computer-aided design (CAD) to do its job. This printer uses layering materials like plastic, synthetic resin, bio-materials to produce 3D objects. They work from the ground up and pile on layer after layer until the object looks exactly like it was speculated.

3D printer

3D printers have high flexibility in what can be printed. They can use plastics to print rigid materials like sunglasses or other small toys. It can also produce flexible objects like mobile phone cases. Some of the 3D printers even can print or create extremely powerful industrial objects by using carbon fiber.

Based on materials that are being used, we can classify the categories of 3D printers:

- Polymer 3D printers

- Metal 3D printers

Polymer 3D printers:

These printers use plastic, polymers, or synthetic resin as raw material. Polymer 3D printer uses below techniques to produce 3D model:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Poly-Jet

- Digital Light Processing (DLP)

- Multi Jet Fusion (MJF)

- Fused Deposition Modeling

Metal 3D printers:

Printers of this category use metals like steel, titanium, etc. as raw material. Metal 3D printer uses following processes or techniques to produce 3D model:

- Direct Metal Laser Sintering (DMLS)

- Electron Beam Melting (EBM)

Units inside this gadget:

Every 3D printer mainly contains the following units to perform its action:

- Frame

- Printing bed

- Extruder

- Feeder system

- Motion controller

- Control unit

- Power supply

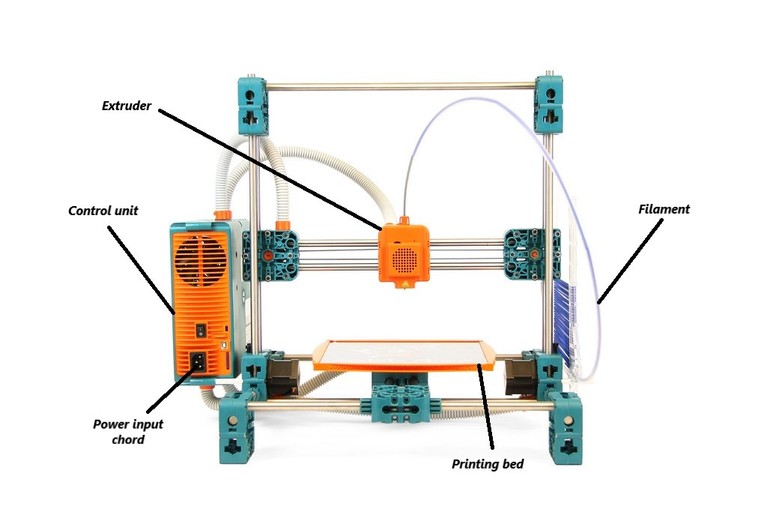

3D printer units

Frame:

As per its name, Frame provides a basic structure to a 3D printer. All the hardware units are attached to the frame. It maintains the stability of the entire machine. The toughness and robustness of the frame provide more durability to the machine.

The manufacturers use different materials and the most common ones are the metallic frame. In the initial days of 3D printing, wood was being used for making consumer 3D printers. However, at present time metals are being used to maintain the high stability and durability of the machine.

Printing bed:

Printing bed provides support to models where models are created. Anyone who has worked with this printer would know what a printing bed is.

The filaments or feeding materials (synthetic resin, metals, etc.) are deposited on the printing bed. It uses the layering technique to produce the complete model. The layering technique means that depositing a layer over another layer to build a complete object.

Different 3D printers use different kinds of the printing bed. Some of them use heated whereas other ones use non-heated printing beds. Non-heated type printing bed may be enough for PLA (Poly Lactic Acid) whereas for advanced material heated printing beds are recommended.

Some of the 3D printers use automatic calibration of printing beds whereas in some of the printers user needs to adjust the printing bed manually.

Extruder:

The extruder is a printing head in a 3D printer. It extrudes the filament (feeding material) and deposits it on the printing bed. The extruder can be segregated into two sections. The first one is “Cold End” and the second one is “Hot End”.

The function of the cold end is to lock the feeding material while pushing it gradually downwards to the hot end.

The hot end that has a nozzle attached to it at the end, maintains a temperature value that is greater than the melting point of the feeding material or filament. The hot end melts the filament that is further deposited on the printing bed.

The extruder is also built from different parts:

- Filament Drive Gear

- Heat Sink

- Thermocouple

- Heating Cartridge

- Cooling fan

- Nozzle

Filament Drive Gear:

This part is also known as extruder drive gear. It is mainly responsible for pushing the filament into the hot end.

Heat sink:

Heat sink unit with cooling fan ensures that the material remains still in a solid-state until it reaches the nozzle.

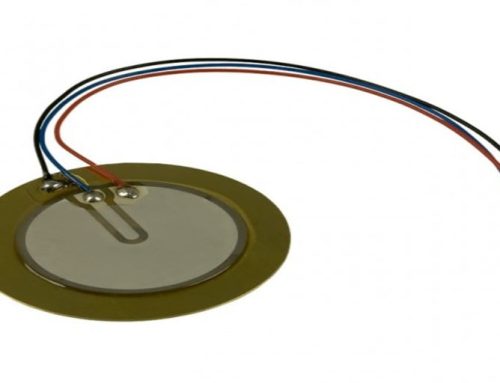

Thermocouple:

It is a temperature sensor. To maintain the correct value of temperature extruder uses this sensor.

Heating Cartridge:

The main responsibility of this part is to heat the feeding material or filament.

Cooling Fan:

To build an object the melted filament is deposited. This melted filament must be cooled down for setting before the next layer gets deposited. The cooling fan is responsible to do this job.

Nozzle:

It is the tip of the extruder. The melted filament comes out of the nozzle for deposition. There is different size of the nozzle present for 3D printers. By using the smaller diameter of the nozzle, one can achieve finer details with greater accuracy.

Feeder system:

The feeder system is mainly responsible to feed material to the extruder unit.

Motion controller:

It is the sense of every 3D printer. Motion controller works along the three axes X, Y, and Z. Motion controller receives instructions from the control unit about the movement they must make.

Control unit:

As per its name, it is the brain of a 3D printer. This unit ensures smooth, accurate, and synchronized processing of the machine.

Power supply:

The power supply unit helps to provide proper power to different units of 3D printer that ensures proper function of the whole machine.

Applications:

Companies all over the world are using 3D printing techniques to generate their various prototypes in a matter of hours or days, instead of wasting months and potentially millions of dollars in research and development (R & D).

Future scopes:

While seeing towards the future scope of this gadget we find that 3D printers are incredibly flexible; not only in the materials they use but also with what they can print. The accuracy of this gadget is very good and speed is also a considerable factor. These qualities of this instrument are making it a promising tool for the future of manufacturing. Many biological research laboratories are using the 3D printer to generate human organs also. Multiple researchers are still doing their job perfectly to improve the level of the 3D printer to make human being life easy and happy.

Thanks for reading. See you soon with another exploration!