Fade up with your noisy and clumsy vacuum cleaner! If yes, then it’s time to move on. Modernization in technology is now going to solve your issues with a vacuum cleaner by placing an intelligent circuit inside. We are here to discuss “Robotic vacuum cleaner”. So, without any further delay just have a look at this intelligent and attractive gadget that is going to change your daily routine or in short words, it is ready to amaze you.

What is a Robotic vacuum cleaner?

As per the name, it is an automated vacuum cleaner. The robotic vacuum cleaner was introduced by Swedish manufacturer “Electrolux” unveiled its model in 1996 called the “Trilobite”. Six years later in 2002, the US company “iRobot” launched the very first model of the modern robotic vacuum cleaner, and its name was Roomba. Nowadays various robotic vacuum cleaners are being used but all of them have some common features like they have some type of navigation system to move them across the floor with certain conditions, contains dustbin to collect dirt, use suction and some kind of brush roller like a classic vacuum cleaner to remove and collect dirt from the floor and most importantly they all are cordless and need to recharge between cleaning cycles.

Robotic vacuum analyzer with charging dock

Units inside this gadget:

This gadget contains multiple units to perform its functions properly. Here we are going to discuss some important units involved here:

- Sensors

- Vacuum suction pump

- Control unit

- Charging docks

- Wireless module

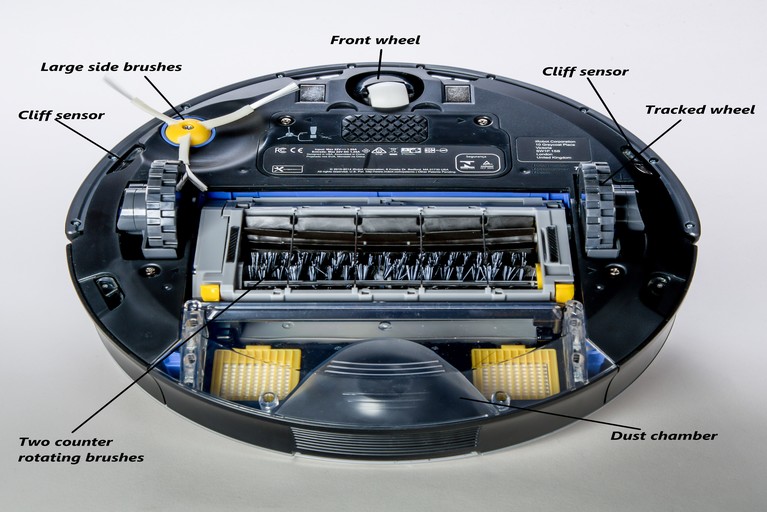

Bottom side of Roomba

Sensors:

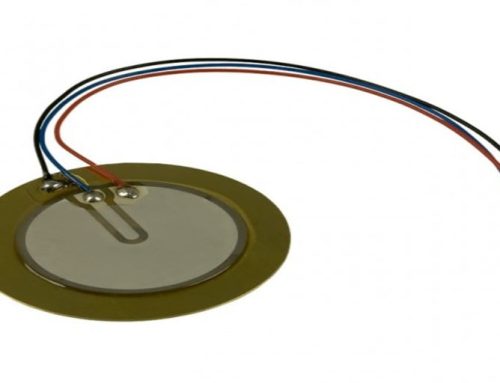

It contains several sensors to perform and calculate different operations. Most of the sensors are being used for navigation and control purposes. Some of them are given below:

Cliff sensors:

A cliff sensor is an important unit in robotic systems to avoid excessive drops. For example, Roomba models come with a cliff sensor to prevent drop from stairwells or ledges. This sensor can be mechanical, optical, or ultrasonic, however, they all are doing the same job.

Mechanical type sensor is simply making contact with floor that runs along with it and when a large drop off is encountered then sensor tells the control unit that it has reached a drop-off.

An optical type cliff sensor uses an LED that shines onto the ground at an angle that is picked up from a photodetector. When the robot comes across a large drop-off, the reflected light from the LED is no longer detected into the photodetector, and the sensor tells the control unit about this.

Whereas ultrasonic cliff sensor simply determines the distance to a surface, and when the distance changes rapidly, the sensor informs to control unit.

Object sensors:

These sensors are responsible to detect objects. As we know object detection is a critical task in the automation industry. Whether detecting the presence of the object passing by on conveyors, the closure of the door, etc. it is still difficult to detect the object.

There are many different object sensing technologies are being used nowadays, some of them are using machine learning to achieve their goals. Here we are going to present a brief description of some object sensors:

Electro-Mechanical:

This kind of object sensor is a basic electromechanical switch. These devices contain a sensitive micro switch that changes its state in contact with the object. Physical contact with the target object is not always possible or desirable that is a limitation in this object sensor.

Pneumatic:

Pneumatic-type object sensors utilize compressed air and a sensitive diaphragm valve to detect the presence of the object. Compressed air streams from a very narrow perforation until any object blocks the stream. Blocking of the air stream creates a minute change in air pressure and this change is being detected by a downstream diaphragm switch that produces an electrical control signal for the control circuit.

Magnetic

These object sensors are using two basic principles. The first one is Reed contact and the second one is Hall effect transducer. In both cases, the presence of a magnetic field produces a change of state in an electrical signal. The failure rate of Reed switches is high as compare to Hall switched. That’s why many designers preferred Hall switches over Reed switches.

Inductive:

Inductive object sensors are also known as proximity switches that detect a disruption in the magnetic fields due to the presence of any metallic object. The reliable detection distance varies and it depends on the type of the metal and also the amount of the metal that comes into the sensor range. These sensors come in several sizes and shapes. One main limitation of an inductive object sensor is that it detects metallic objects only.

Capacitive:

This kind of sensor comes under a type of proximity switch. These proximity switches detect non-metallic objects that have dielectric constant different from air. This property makes them ideal to detect various objects like wood, plastics, liquid, fabric, etc. Once the target object comes into the range of this sensor, electrostatic fields between capacitive plates change abruptly.

Photoelectric:

Photoelectric type object sensors use different technologies depending on their application. But they all use the same principle. They all send out a light beam and then detect a change in reflected light intensity. Laser sensors have come into this category and they can send light beam 50 meters or longer. Transparent objects, or objects with a varying surface finish, can be problematic for photoelectric type object sensors.

Ultrasonic:

These devices transmit a short burst of ultrasonic sound waves toward the target object and that object reflects the sound back to the sensor. The sound wave is reflected by almost all kinds of solid materials and it does not affect by color or other optical effects.

Wall sensors:

Most of the robotic vacuum cleaner treats walls as objects. They contain an infrared sensor that detects walls so they can follow right up to the edge without bumping or colliding against them. Wall sensors are good for edge and corner cleaning without any collision.

Dirt sensor:

This sensor is not common in all robotic vacuum cleaners. These are located on the bottom of the cleaner near the agitator brush. The main function of the cleaner is to inform the control unit to increase the suction level to clean dirt efficiently.

Vacuum suction pump:

The vacuum suction pump in this gadget works in the same manner as whatever it was doing in old vacuum cleaners. The suction pump in the robotic cleaner is compact and efficient. Most of the robot vacuum cleaners have at least one spinning side brush on the front corner which is the first point of contact for dirt. Side brushes stick out from the vacuum body and sweep dirt inward the dusting panel.

Control unit:

This is the brain of a robotic vacuum cleaner. It is the motherboard of this device and responsible to control every unit of the cleaner. Arduino or Raspberry-Pi is being used for this purpose. The type of control unit depends on the functionality of the cleaner.

Charging docks:

All of the Robotic vacuum cleaners are cordless and require a rechargeable battery for their operation. Eventually, this battery is the power supply for cleaner during its function. With the advancement in technology, this cleaner becomes intelligent and it can return to its charging point or dock automatically to recharge its battery. Some of the advanced models of the cleaner return to their job after completion of the recharging process.

Wireless module:

This module is generally integrated with the control unit of the gadget. As we know wireless units provide features to control the device. Bluetooth, Wifi, or Internet connectivity is being used to control your robotic vacuum cleaner.

Working of Robotic vacuum cleaner:

When you start this modern gadget it initializes its pre-build program and makes a calculation for the dusting or cleaning area. You can also decide that where this gadget needs to go for cleaning and where does not. After completing its calculations all the sensors come into the operation to perform their specified task. In this way, these cleaners are working nowadays.

Applications:

These cleaners are being used widely in households, entertainment, and security sectors also. It can perform some functions similar to Humanoid Robots.

Thanks for reading. See you soon with another exploration!

Who knew?

[…] magnitude of a given pressure or force and create an output signal. The most common types of force sensors include Load cells, Strain gauge, and Force sensing […]