It was a time when we were using an electric heater to cook food. One big problem with electric heater is that it is very dangerous to use. There are always possibilities of electric shocks. Another disadvantage is that it is also less durable.

Induction cooking is a good alternative to the electric heater as well as the household LGP cylinder. Induction stove technology was discovered in the early 1900. It was first time introduced in 1933 at the world fair in Chicago.

What is an Induction-stove?

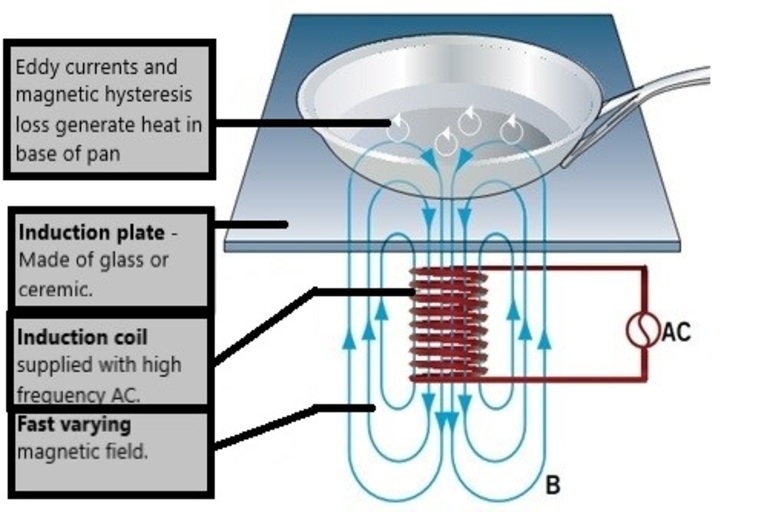

It is an appliance that converts input power into a magnetic field. This varying magnetic field causes to generate heat. An induction stove works on the principle of Electromagnetic induction. Before going inside into the induction stove let’s discuss a little about electromagnetic induction.

Electromagnetic induction in Induction stove

Electromagnetic induction is a theory that was discovered in 1830 by a well-known scientist Michael Faraday. As per this theory, when you pass an alternating current (AC) through the conductor or a coil, a magnetic field gets generated around the conductor or coil.

Using the same principle, the manufacturers of induction stoves put a copper coil below the cooking wall or glass of the Induction stove. When you switched ON the Induction stove, the input AC supply enters into the internal circuits.

This circuit enhances the frequency of input power and at the end output of the circuit passes through the copper coil. When you put a cooking pot made of any ferrous or ferromagnetic material on the induction stove, a small current of approximately one volt is induced on the bottom of the pot. This current has an associated magnetic field, which induces other smaller currents. These currents are known as Eddy currents. These currents have their magnetic fields. The frequency of current flows into the copper coil is very high (more than 1000 Hz). As of result frequency of eddy currents are also high. As we know ferrous materials like iron or steel are having high electric resistances. When eddy currents run through these materials they generate heat into the pot and the remaining heat is generated by changes in the magnetic field (associated with Eddy currents). The heat generated by this magnetic field is also known as magnetic hysteresis loss. The generated heat from the pan flows directly into the food or water inside that pot.

Inner units of Induction stove:

An induction stove contains below units:

- Induction circuit board

- Control panel

- Induction coil

- Induction plate

Induction circuit board:

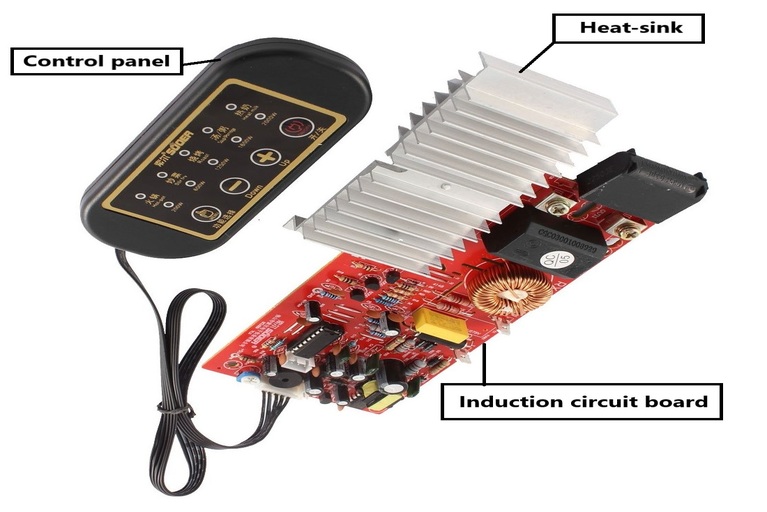

The induction circuit board of the induction stove has two parts. The first part is working as a voltage regulator and the second part work as Cyclo-converter. A Cyclo-converter is a device that boosted the input signal current to a high-frequency current. This high-frequency current works as input power to the induction coil.

Induction stove circuit board module

This circuit contains some solid-state components that are responsible to generate the high-frequency output current. These solid-state components generate a large amount of heat during their operation.

As of result, it is necessary to remove this additional heat by using a proper heat-sink and cooling fan. The induction circuit board also contains timer IC’s to set the cooking time and controlling the amount of heat.

Control panel:

It is a user interface panel. This control panel contains some value indicators, touch or push buttons, and a few IC’s and resistors. By using this panel user can adjust the amount of heat and time for cooking.

The Control panel is internally connected with the induction circuit board. When end users choose some cooking time or amount of heat then the control panel sends these values to the main circuit board or induction circuit board to perform the required actions.

Inner units of Induction stove

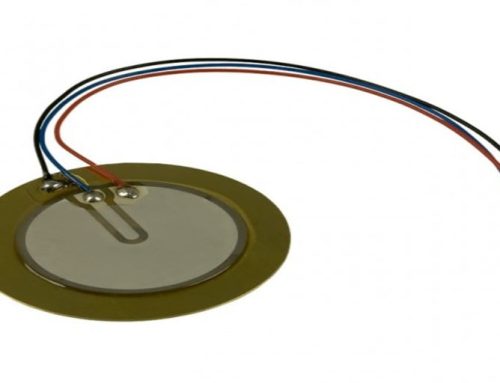

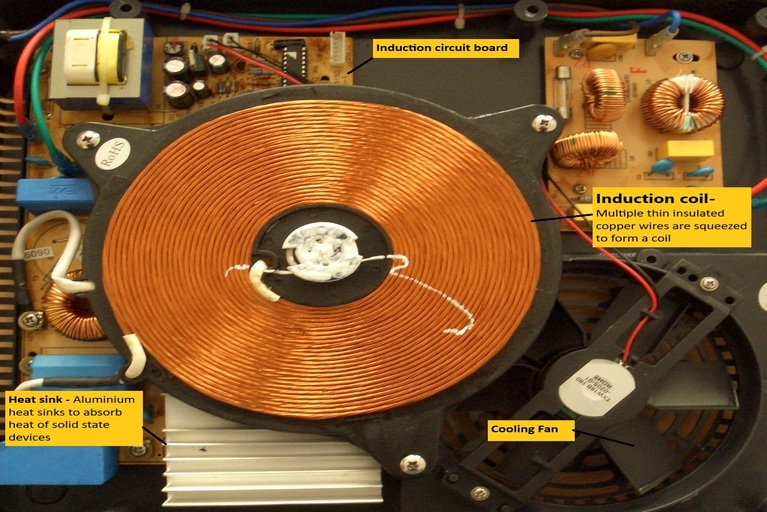

Induction coil:

It is made of copper. Multiple thin insulated copper wires are squeezed to form a coil to generate a good amount of heat. This coil is mounted under the cooking surface and a high frequency (20 to 40 kHz) current is passed through it.

The current in the coil generates a dynamic magnetic field and this dynamic magnetic field generates eddy currents at the surface of the induction pot or cooking surface. Most of the heat of the cooking surface is generated by eddy currents and the rest of the heat at the cooking surface is generated by magnetic hysteresis losses. In this way, this induction coil generates heat for cooking.

An alternative of household LPG cylinder:

In an induction stove, most of the heat is produced in the cooking pot and much more of the energy goes into the food. That’s why induction stove or we can say induction cooking is more energy-efficient than most other methods. On the other side induction cooking is also around 25 to 50 percent is more efficient and safer than household LPG. In the end, we can say that induction cooking is a good alternative to other cooking methods.

Thanks for reading. See you soon with another exploration!