A capacitor is a component that can store electric energy in the form of electronic charge. The form of practical capacitors varies widely, but in all of them, internal structures and working concepts remain the same. In a capacitor, an insulating material that is known as the dielectric is placed between two electric conductors. The conductors can be thin films of metal, aluminum foil, etc. The dielectric material can be glass, ceramic, plastic film, air, paper, mica, etc. Capacitors are widely used in several electronic and electrical equipments. We know that a resistor dissipates electrical energy whereas a capacitor stores or adsorbs energy.

History of capacitor:

It was October 1765 when a German physicist Ewald George Von Kleist found that charge could be stored by connecting a high-voltage source (like an electrostatic generator) by a wire to a volume of water in hand hand-held glass jar. In this model Von Kleist’s hand and water layer act as metallic plate of capacitor.

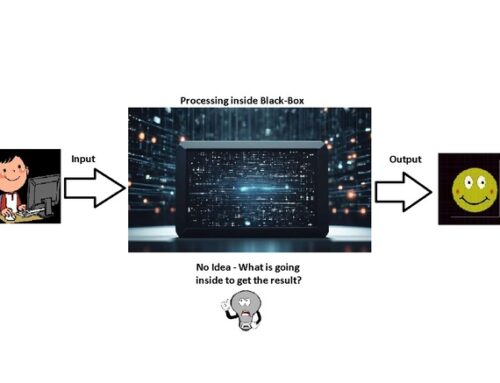

Working principle of capacitor:

The capacitor working principle is very simple. When an electric potential is applied across the capacitor plates then an electric field develops across the dielectric material, causing a positive charge (+q) to collect on one plate and a negative charge (-q) to collect on the other plate. Once a battery has been attached to the capacitor then a circuit current flow for a certain period of time and stops flowing in the circuit once the capacitor stores charges as per its defined capacity. However, if an alternating voltage or current is applied across the leads of the capacitor, a circuit current also known as displacement current can flow.

Types of capacitors:

In electronic circuits, various types of capacitors are being used. Each of them has a similar working principle but has different specifications like charge storing capacity, voltage rating, tolerance, etc. The comparison between the different types of capacitors is typically made with regard to the insulator or dielectric material used between the conductor plates.

Commercial capacitors are made from metallic foil interlaced with thin sheets of paraffin-coated paper as a dielectric material between plates. Some capacitors are often constructed from ceramic material and dipped into an epoxy resin to seal and prevent moisture.

Whatever the material used inside a capacitor it is an important component in electrical and electronic circuits. Here we are describing some of them:

- Dielectric Capacitor

- Film Capacitor

- Ceramic capacitor

- Electrolytic capacitor

Dielectric Capacitor:

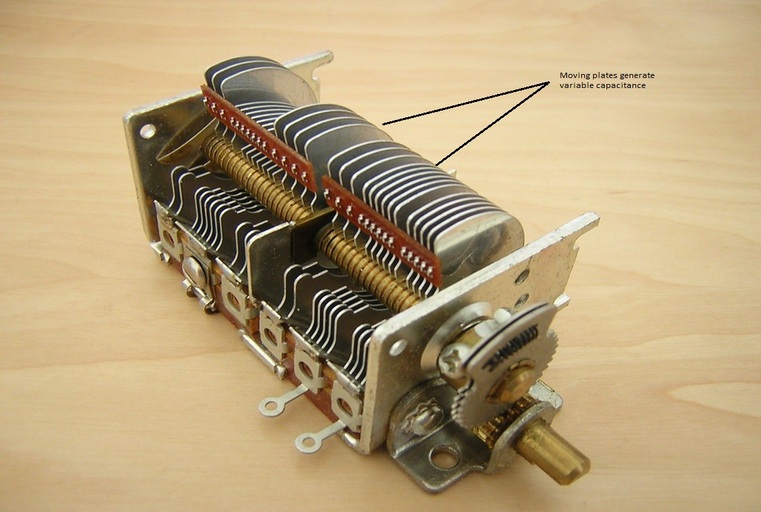

Dielectric capacitors are usually of the variable type those are having a variable capacitance that is required for tuning in transmitters, receivers, and radios. Variable-type dielectric capacitors are multi-plated air-air-spaced types that have a set of two kinds of plates. The first type is static whereas others are moving type. The position of the moving plates with respect to the fixed plates decides the capacitance value. The capacitance value is generally at maximum value when these plates are fully overlapped with each other. Most probably you have seen this kind of capacitor in old model radio receivers.

Variable capacitor

Film Capacitor:

These capacitors use thin films of synthetic material such as polyester, polystyrene, Teflon, etc. for capacitor dielectric material. Every thin film material has its own merit with certain limitations. Film-type capacitors are available in the range between 5pF (pico farad) to 100uF (microfarad). Film capacitors also come in different shapes. Based on the shape and structure of the thin film this capacitor is available in the below variant:

- Film-foil capacitor

- Metalized film capacitor

Film-foil capacitor:

These are made by using two sheets of plastic followed by the sheets of Aluminum foils. These sheets are then folded in the shape of a cylinder. The electrical connectivity is made by connecting the aluminum foil to the leads. Here aluminum foils act as Electrodes. In film-foil capacitors plastic sheet works as a dielectric material and by changing the thickness of the plastic sheet capacitor property can be changed.

Metalized film capacitor:

In this type of film capacitor, the plastic film has a very thin layer of metallization deposited onto the film. The thickness of the metal layer is very low and it is between 0.02 to 0.1 micrometers.

Film Capacitor

Ceramic capacitor:

When we look into the history of capacitors we find that ceramics were one of the first materials to be used in the production of capacitors. A ceramic capacitor uses ceramic as a dielectric material. These capacitors are available in different shapes and sizes, some of them are tubular and disc type. In modern electronic equipment multi-layer ceramic capacitors, otherwise named ceramic multi-layer chip capacitors (MLCCs) are being used. They are made using source-mounted technology (SMD) and are widely used in billions of electronic circuits every year. Ceramic capacitors are small in size with low capacitance (1 nano-farad to 1 micro-farad) and have a lower maximum voltage rating. They do not have polarity similar to dielectric and film capacitors, which means they do not have any positive or negative terminal and you can use it in an AC (Alternating Current) circuit. The ceramic capacitors have low parasitic capacitance, resistance, or inductance, which makes them suitable for fine-tuned high-frequency applications.

Ceramic capacitor

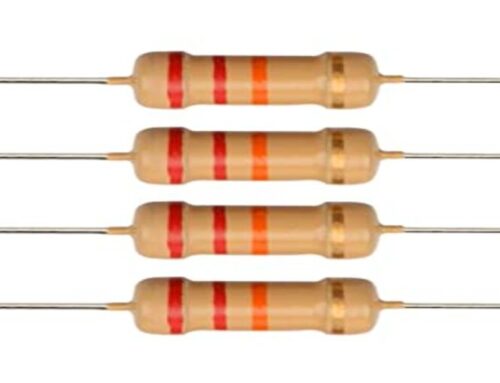

Electrolytic capacitor:

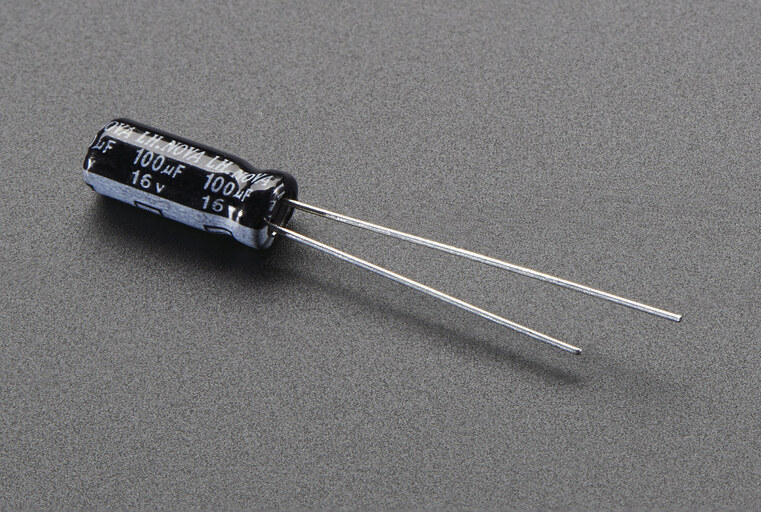

This capacitor has having high value of capacitance and is small in size because it contains a specific electrolyte to achieve the capacitance. The specific electrolyte is a liquid or gel-type material that contains a high volume of ions. Most of the electrolytic capacitors are polarized. The polarization represents that the voltage on the positive plate (terminal) must always be greater than the voltage on the negative plate (terminal). The main benefit of the electrolytic capacitor is high-value capacitance but it also has some limitations like leakage current, value tolerances, and limited lifetime.

Electrolytic capacitor

This is the brief introduction of Capacitors. Thanks for the reading. See you soon with another exploration!