Resistances or Resistors are fundamental electronic components. A resistance is specifically designed to handle a fixed amount of electric current. Electric resistance comes in a vast range from micro ohm to thousands of megaohm. This is resistance but how is it made? Let’s find it here.

Resistance Technology:

Resistances have come in two categories. In the first one resistance value is fixed means we are not able to change or vary the resistance value. In the second category resistance value can be varied by using a moving shaft or some other mechanism.

Fixed resistances:

Fixed resistances are classified into four major categories, which are given below:

- Carbon composition resistance

- Thin-film resistance

- Wire wound resistance

- Surface-mount resistance

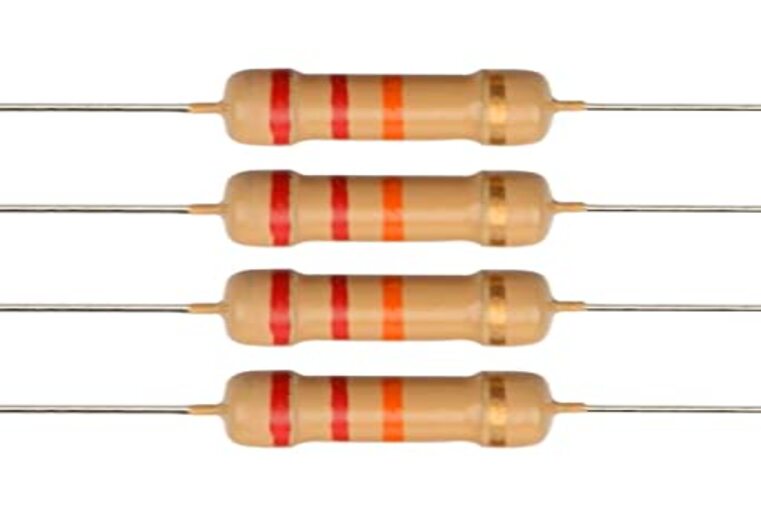

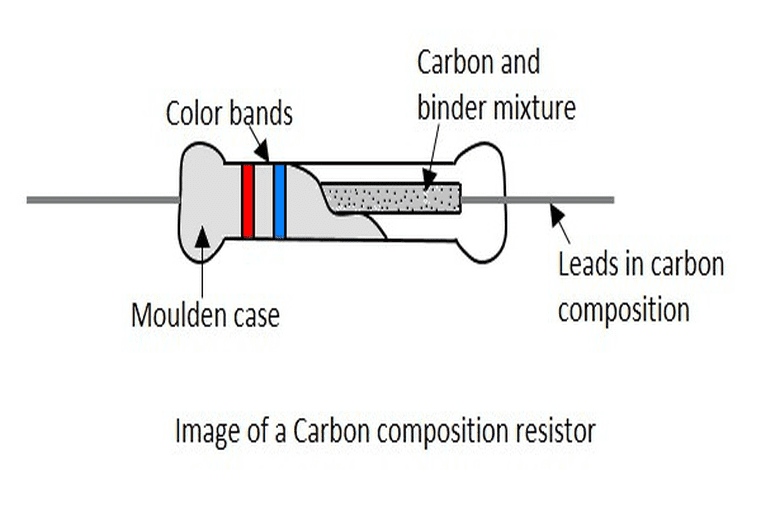

Carbon composition resistance:

Carbon composition resistance consists of solid resistive material connected with metallic caps to connect wires. The resistive material of this resistor is generally made from a mixture of graphite (carbon), ceramic, and resin. Resin holds the mixture together. The resistance value of carbon composition resistance is determined by the ratio of the mixture material. A higher concentration of carbon in the mixture results in a lower value of resistance. These resistances were popular in the 20th century but are not popular for general use now as other types of resistances have better specifications, like voltage dependence, and tolerance. Carbon composition resistances change value when working with over-voltage which means the resistance value of these resistors gets changed. Also, these resistors are sensitive to moisture and have poor stability. These resistors have non-inductive behaviour which provides benefits when used in high-frequency voltage.

Carbon composition resistance

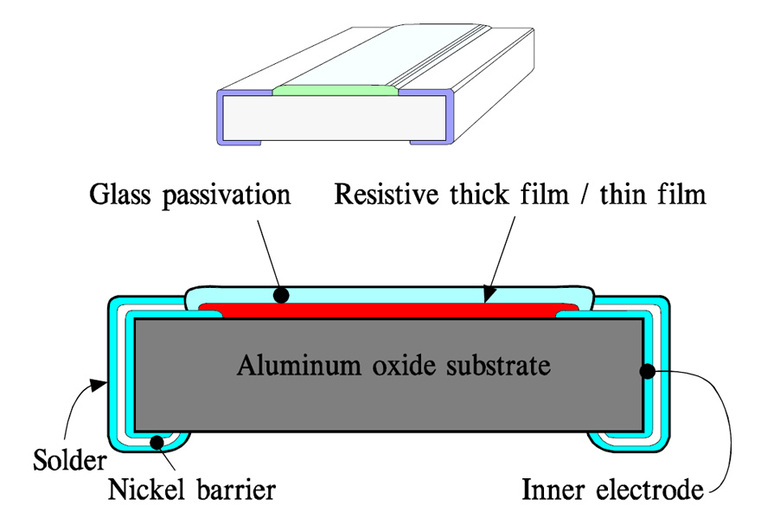

Thin-film resistance:

Thin-film resistances are made by vacuum deposition (this method is known as sputtering) of the resistive material onto an insulating substrate. The film is etched in a similar way as a subtractive method. In this process, the surface is coated with a photo-sensitive material, then covered by a pattern film, irradiated with UV light (ultraviolet light), and then the exposed photo-sensitive coating is developed, and the underlying thin film is etched away. Thin film resistors are usually specified with tolerances of 1% to 5% and a low noise level.

Thin film resistance

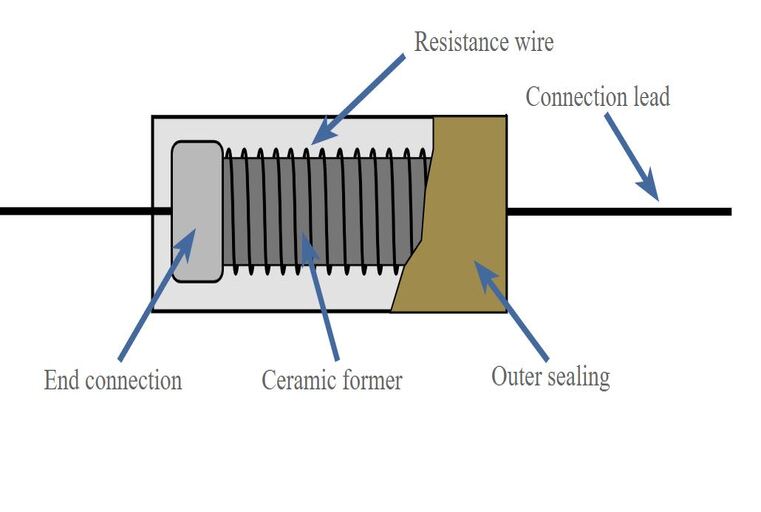

Wire wound resistance:

A wire-wound resistance is an electrical passive device that limits the electrical current flow in a circuit. These resistances are constructed by using resistive wire with a high-temperature coefficient that is wound around a central core that is usually made of ceramic. Wire wound resistances are typically used in high-power and industrial applications such as electrical fuses. These resistances have a high tolerance, good temperature stability, the ability to absorb pulses, and low noise. However, it has some limitations in high-frequency applications. These resistances show inductive behaviour at high-frequency voltages.

Wire wound resistance

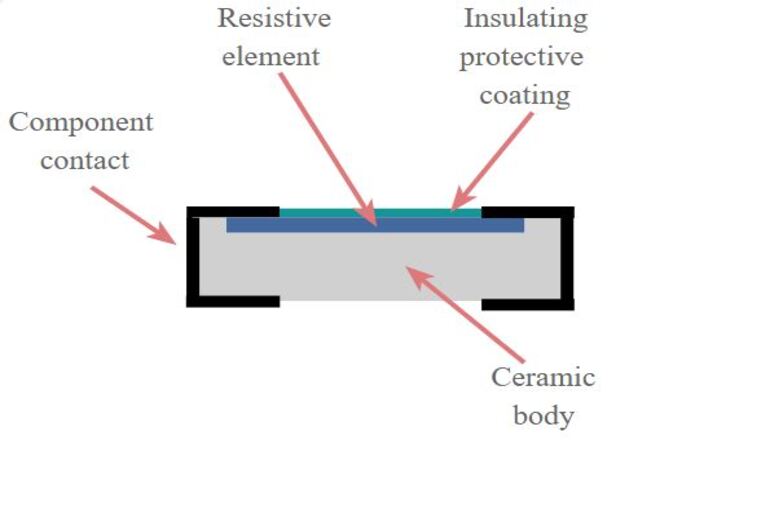

Surface-mount resistance:

A surface mount resistor is a small rectangular ceramic body with silver conducting ends to connect it to an electric circuit. These are also known as SMD (Surface Mount Device) resistors. SMD resistances are enough small to save space on printed circuit boards. Surface mount resistance has good temperature stability and better tolerance. While choosing it for your circuit you need to consider power rating for better performance.

Surface mount resistance

Variable resistances:

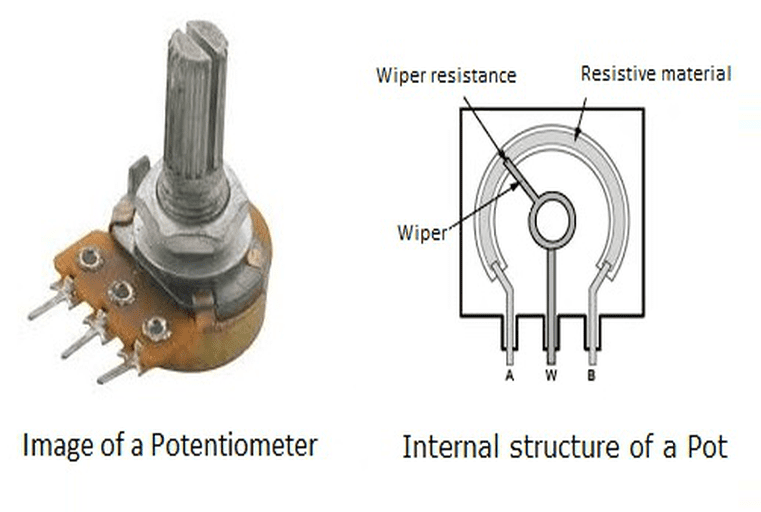

Variable resistance is an electronic component in which electric resistance can be adjusted by moving contact. This is a type of electromechanical transducer that typically works by the movement of the wiper over a resistive element. When variable resistance uses three pins for the function it is called a potentiometer. If variable resistance has two pins only then it is called a rheostat. Some of the variable resistances contain electronic tuning; they do not require mechanical action. Electronically adjustable variable resistors are called a digital potentiometer. Variable resistances can be classified into three major categories:

- Potentiometer

- Rheostat

- Digital resistances

Potentiometer:

The potentiometer is a three-pin variable resistance. It functions as a resistive voltage divider and is typically used to generate a voltage signal depending on the position of the moving shaft over resistive material. This type of resistance can be used in several electronic types of equipment like Radio and Tape recorders for volume control, tuning of circuit voltage or current, and more. If you are a circuit hobbyist, then probably you have tuned this potentiometer at least one time by using a screwdriver.

Potentiometer

Rheostat:

In view of architecture, rheostats are similar to potentiometers but are not used as a potentiometer. A rheostat is being used as a variable resistance. As we have already mentioned, it is a two-terminal variable resistance. One terminal is connected with an end of resistive material whereas the other terminal is connected with a moving terminal or wiper. Initially, a rheostat is made to control the power of various circuits like to control light and fan speed. At present, these are not being used much because they are inefficient for power control. As of now, rheostats are replaced by electronic switching.

Rheostat

Digital resistances:

Digital resistances are electronically tuned variable resistance. They can change resistance in discrete steps and are often controlled by some specific digital protocols such as I2C. Digital resistances are a kind of integrated circuit. They can adjust their resistance value by using some predefined condition.

Thanks for reading. See you soon with another exploration!